Main bearing

Lagerwey invented the single main bearing concept for wind turbines and has now developed a new standard for its modular main bearing. Two robust and compact tapered roller bearings form the bases of an oil lubricated and smart modular unit. The rigidity and over-engineered housing concept results in lifetime reliability. All of our bearings are repeatedly tested in our factory before final assembly. The main bearing operates at low temperatures, which increases the longevity of the seals.

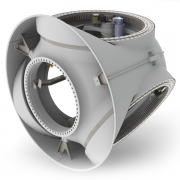

Rotor Hub

The hub transfers the forces of the blades into the drivetrain. Lagerwey has designed the hub to be easily accessible from the inside of the turbine (through the main bearing in the generator). This allows for safe and comfortable service and maintenance operations by our mechanics.

Our pitch drive system has an AC main drive with emergency DC backup, allowing the blades to be pithed out of the wind during grid failure or other events where the AC drive is not available.

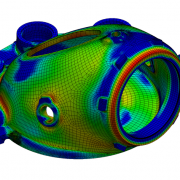

Drive Train

Lagerwey generators are integrally designed with the nacelle and hub. The forces on the turbine flow directly from hub through to the generator axis and the nacelle construction, this results in an optimum force distribution into the tower. Lagerwey avoids the problems that conventional drive trains still experience today without the need for complex machine beds and long shafts. The short axis and the direct, simple transmission of the forces creates a very stiff structure which results in minimum deformation. This reduces wear and tear and extends the life cycle.

The generator itself has a very high torque density because of the magnetic topology and naturel cooling. This enables a compact generator design compared to other direct drive concepts. The compact design also results in easy transportation, lower transportation costs and low RADAR profiling.